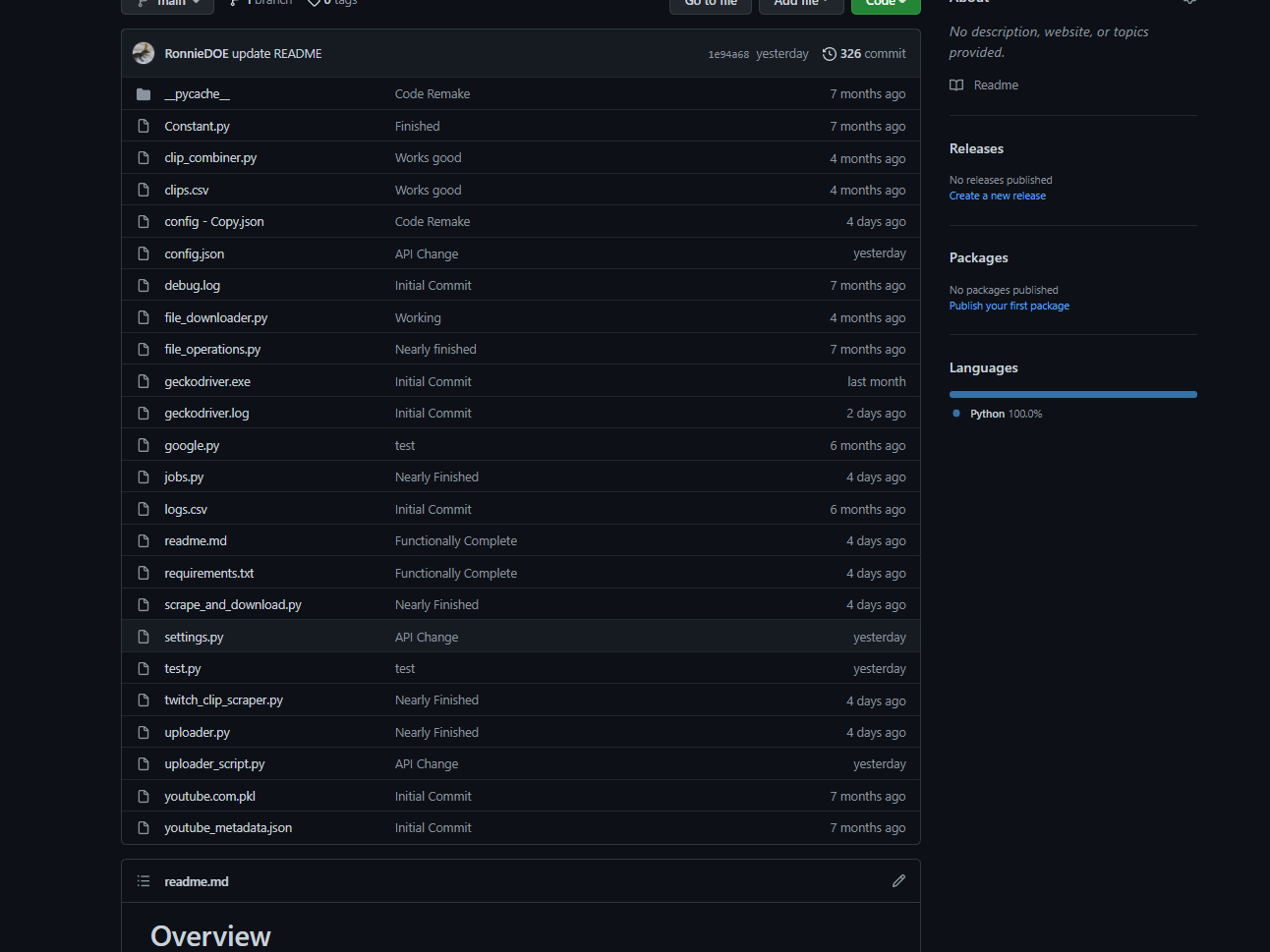

These are GUI pieces I created in Delta's HTLM/CSS graphics suite. I spearheaded all advanced graphic design within Automated Controls easily known as the most experienced engineer in graphics design at Automated Controls Inc. Working through the Delta Forums and other partners to help them and also help Automated Controls Inc. achieve some of the most state of the art designs that are extremely functional while also being user friendly and intuitive. Beyond my graphics work I have assisted with creating, setting up, and even installing for projects. As a multifaceted engineer, I also contributed to creating, servicing, and even installing for projects.

This is a zoned floorplan from one of many projects I've taken part in. Many of our clients know very little about the HVAC field or the software tied to controls, so making a user friendly interface is a high priority for me.

This is the page that comes up when clicking on any of the spaces.

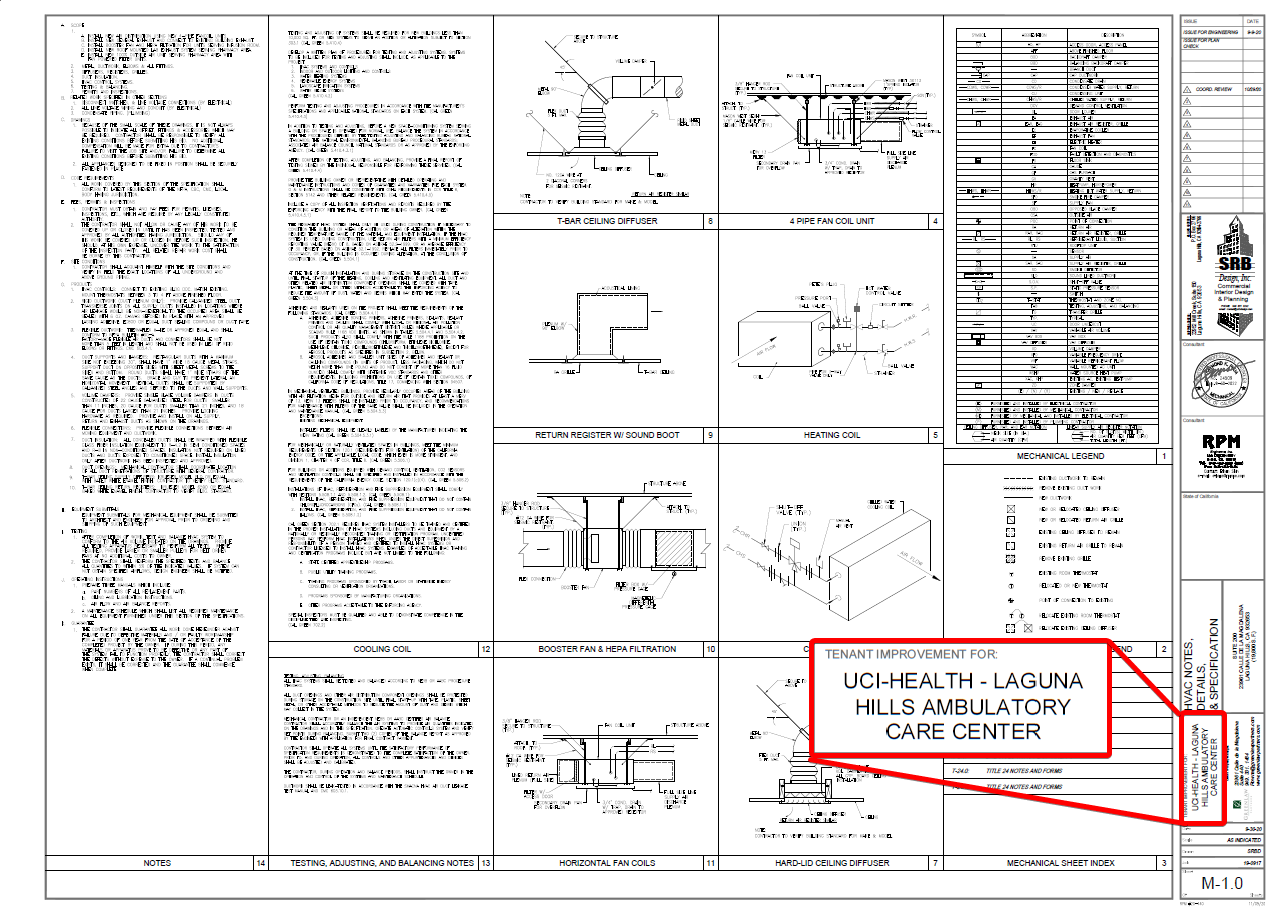

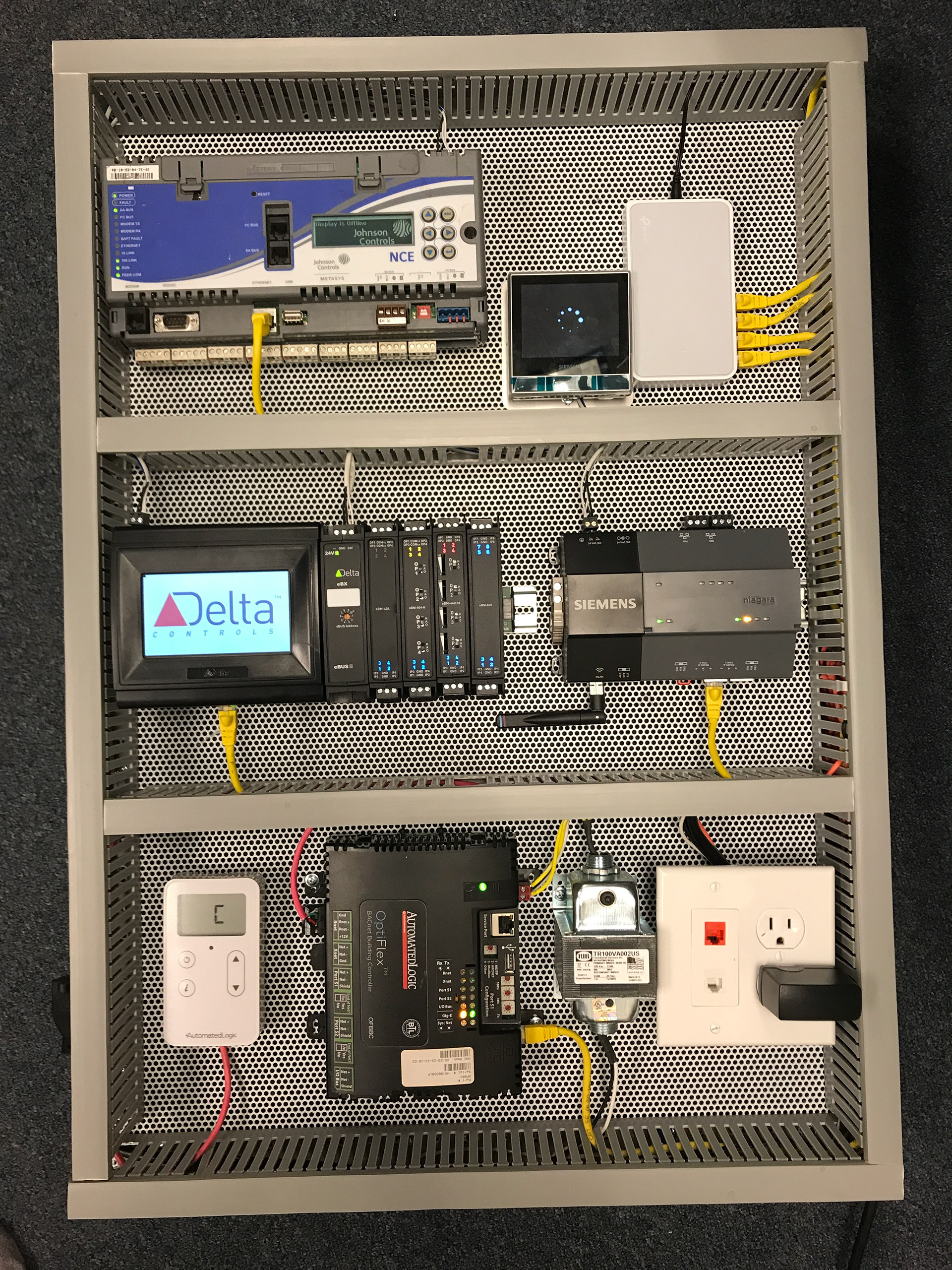

I'm thoroughly familiar with BACnet standards, typically used ports, and creating databases for large scale or smaller scale deployment. I have assisted and created graphics and databases for equipment that some may find out of the HVAC realm to a degree, such as working with my fellow engineers at Palomar College to create databases for Fume/Flow hoods to adjust the suction rate in a scaling fashion based on how open the hoods were in student labs.

This is one of the scalers in the delta controller's database for the aforementioned fume hoods, all of which were all calibrated manually.

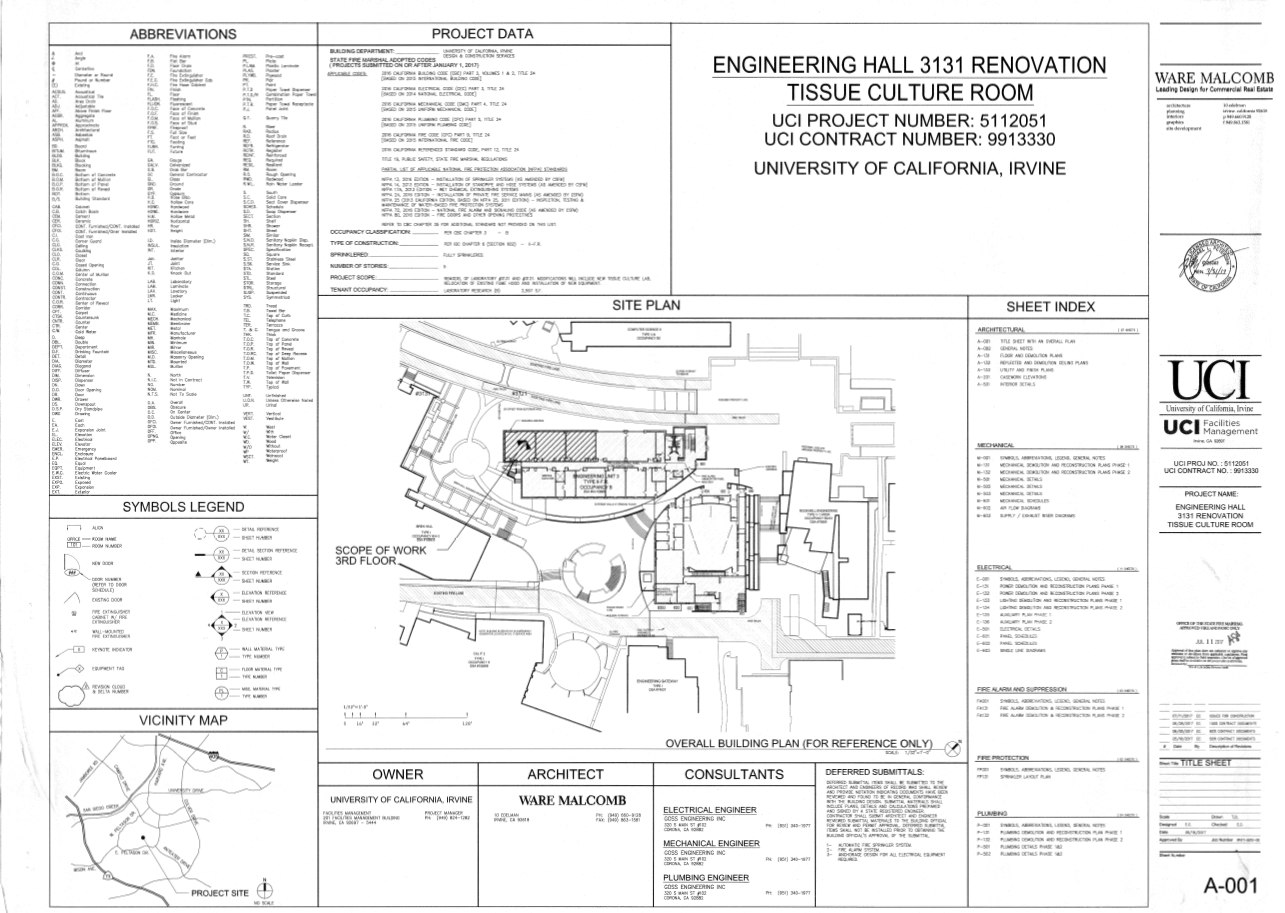

Below is an embedded submittal of one of the many projects I have worked on in my years at Automated Controls Inc. (With the property name censored) I did the vast majority of the engineering for this project and many others, noting that even 3 years ago early into the controls industry I was making strides in the engineering department. For this projects I also created the graphics, and setup various controllers with the specialized databases needed.

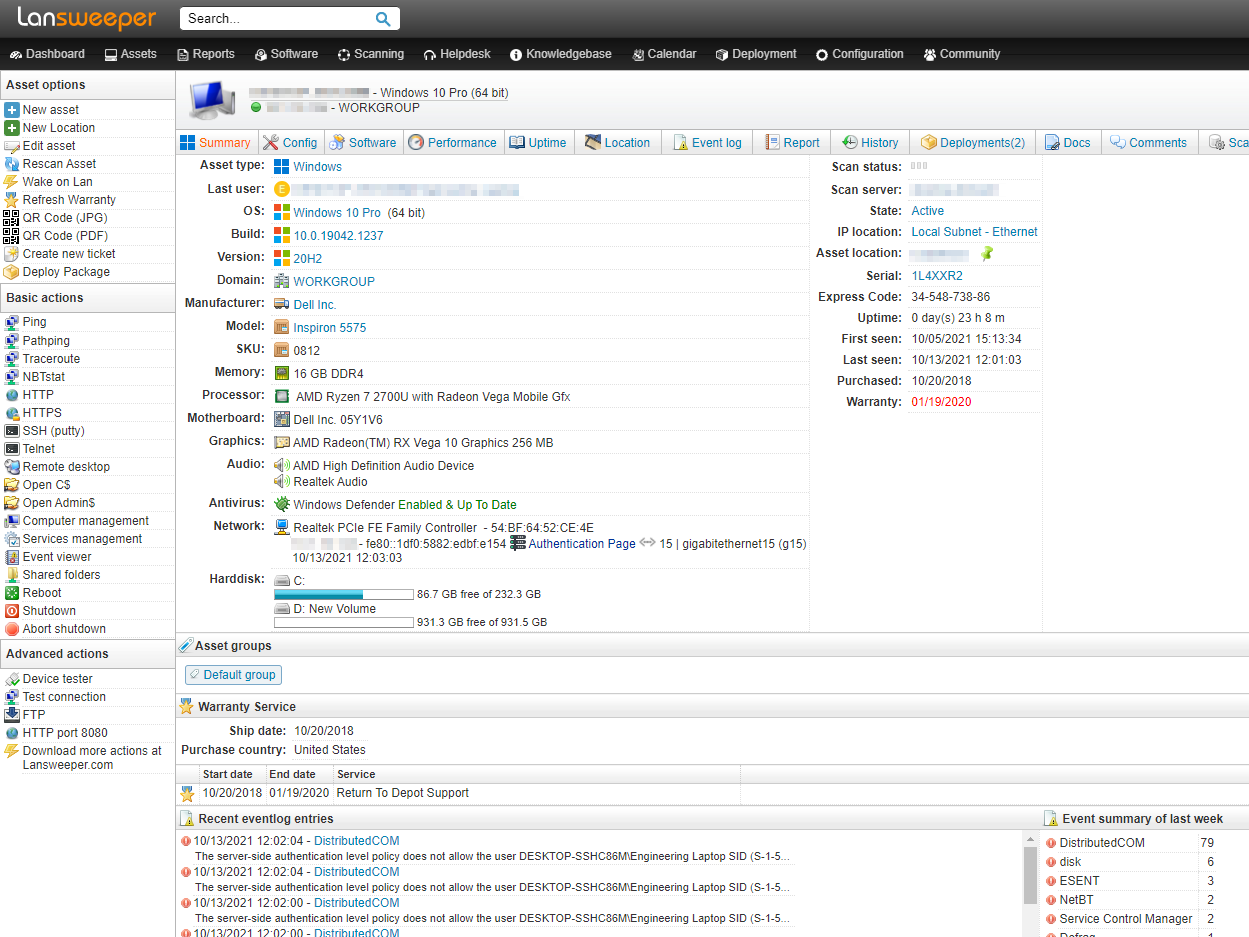

I have worked with hundreds of other sites, and initially I was part of Automated Controls' service team taking calls, fixing client issues, and coordinating with our service field team for repairs. Not too long after (around 8-9 months) I was told I showed a lot of promise and I was promoted to the engineering team while also doing the majority of the companie's IT where I have been for nearly 4 years.

I'm trusted to do nearly all client training for Automated Controls from my demonstrated knowledge of the controls industry, graphics design, and building rapport. I have trained all around San Diego, Beverly Hills, Palm Desert, you name it and I've probably been there for client training. Since I do most of Automated Controls' IT I also do a bit of training for new hires not even in my department so they can hit the ground running.

I researched some of UC Irvine's Mechanical plans in order to best support our sales collaboration with UCI in previous proposals.